When constructing custom-made fiberglass furniture, pools, fiberglass water slides, and infrastructure, planners, and engineers have distinct materials to choose from. Individuals would like to opt for materials like stone, wood, and metal to lay down strong building bases. Selecting quality products means ensuring durability and beauty of the buildings in the long run. Conversely, the availability of these humanmade materials possesses its importance. Products by fiberglass are known for their pricing and ability to match immediate needs.

Concrete infrastructure is of in-depth significance concerning economic growth of an area. Commercial and domestic structures need to undergo design and construction with the right techniques and materials for them to stay in good condition and live for long without rehabilitation. Durable systems of infrastructure like highways, bridges, water systems, and buildings play a crucial role in a healthy growth of the economy. The requirement for corrosion-free and cost-effective construction materials like FRP has attained an unprecedented level.

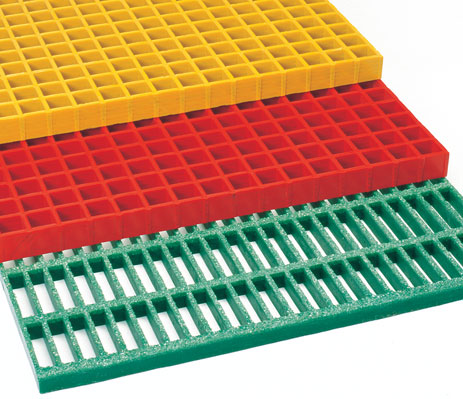

FRP, which are known as composites, have been used for many years in particular sensitive applications that have harsh environments. Excellent results that come from FRP Malaysia products in civil construction and infrastructure has resulted in shifting from the traditional reinforcements to FRP in developed countries like Malaysia. The ability to resist harsh climatic conditions and protecting reinforced concrete against agents of corrosion make fiberglass construction products and bars an incredible alternative to predictable concrete techniques.

The construction industry relies on standards, design codes, and specifications for the materials to be used in the right manner. Previously, fiberglass Malaysia products underwent design, fabrication, and manufacture using general design manuals and codes provided by the concerned authorities. The extensive onsite and academic research has resulted in the development of specific and in-depth design specifications and codes, making it easy to adopt composite materials in the construction industry as an alternative to substandard and conventional materials.

The development of standard FRP codes will assist structural engineers to construct safe and durable projections. Additionally, the presence of these codes paves the way for fiberglass composite materials to become dominant in the market.

Fiberglass rebar is among the most dominant products of FRP being used for reinforcing concrete. Lifting anchors, rock bolting, form ties, and tendons are other FRP construction materials. The distinctive and development properties of these products have gotten a response from the engineers’ community. With the new design specifications and codes, civil engineers have showcased confidence in FRP construction products.

Civil engineers need to be aware of the quantitative and qualitative properties of construction material used in the construction of FRP Trading Custom Made Sculpture. Design manuals, codes, and specifications assist the engineers to understand the application and strength of the material.

With the addition of regular technology, the use of new FRP materials is common. Among other new materials, FRPs are catching up the current market. This material is strong and meets the performance of the most used materials. Fiberglass material comes from an affordable range, convenient to clean, light in weight, and easy to install. Its performance is perfect against corrosive agents and environments. For this reason, FRP is occupying top positions in the selection all infrastructure kinds.